Key Features

- Code-compliant: engineered to meet the latest building code and industry standards

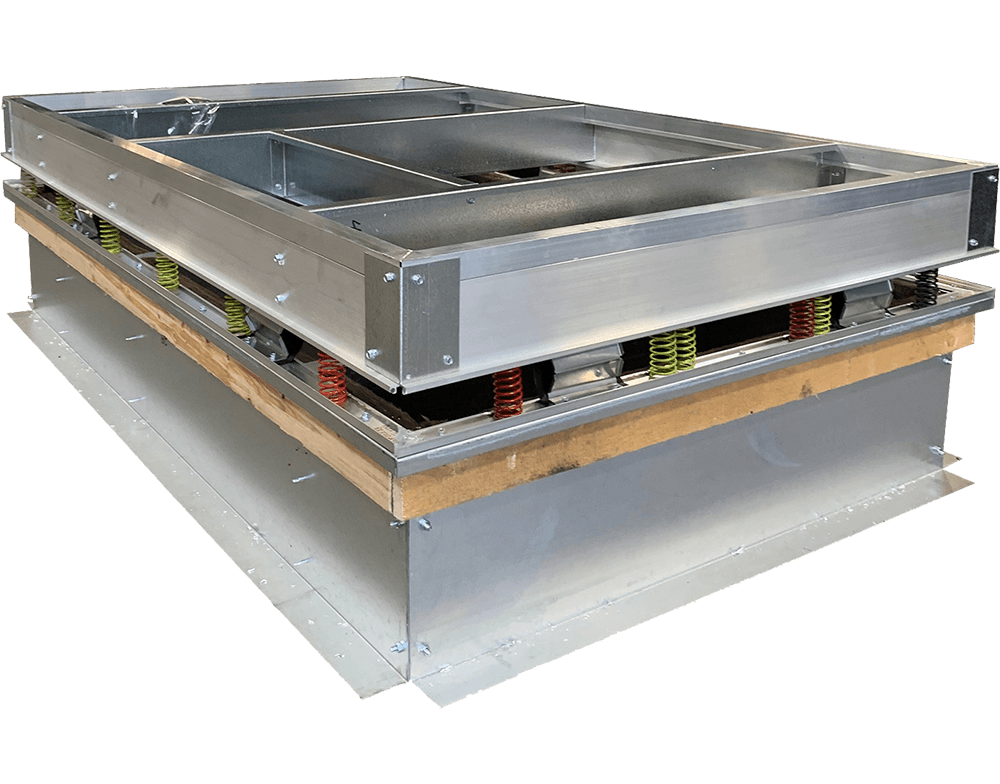

- One-piece welded construction

- Weather-tight and fully insulated with 1” duct liner

- Designed using supply and return transitions for low static pressure

- Heavy-gauge galvanized steel

- Maximum energy savings

- Reliable, easy to install

Available Options

- Wind/seismic ratings

- Vibration isolation

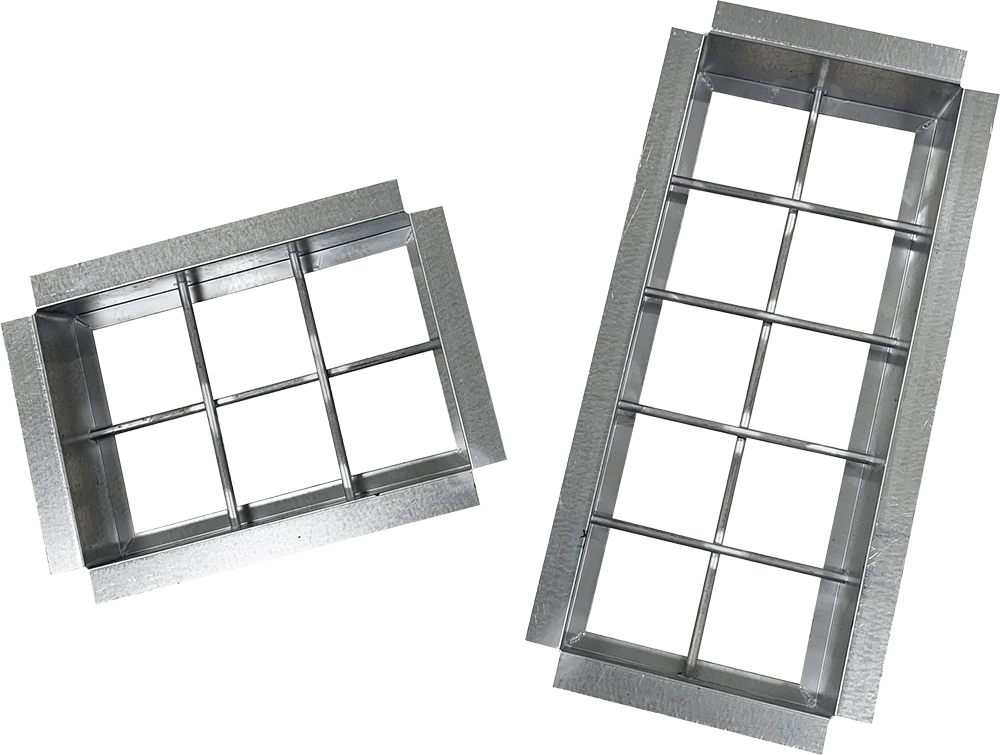

- Filter racks

- Horizontal supply/return

- Access doors

- Acoustical panels

- 2” duct liner

- Blank off panels and equipment supports

- Service platforms

- Factory field measure services

- Lifting lugs

- Custom configurations

Applications

- Compatible with all major OEM HVAC brands

- Ideal for retrofit and replacement projects

- Suitable for commercial, residential and industrial rooftop installations

- Engineered to meet local codes and standards

- Full customizable

Installation Advantages

- Factory-built to exact specifications for a perfect fit

- Reduces on-site modification and labor time

- Ships ready to install — minimal field assembly required

- Live product specialists available to assist with installation process

Quality You Can Count On

- Precision-engineered using advanced 3D modeling techniques

- Built to ISO/ASHRAE/ASCE/local/international standards

- Every adapter inspected before shipments

- Proven to maintain unit airflow and system performance

- Proudly union made in the USA, built to last

Are All Curb Adapters Created Equal?

Not even close.

Low-cost curb adapters might look like a deal—but they can cost you far more in performance and efficiency. Many manufacturers design adapters without considering optimal airflow. Their plenumized designs often create high static pressure, leading to airflow issues, reduced energy efficiency, and costly callbacks.

At Cambridgeport, we engineer our curb adapters differently. Every product is designed with airflow in mind, ensuring reliable performance, energy savings, and a retrofit you can trust—every time.

Every Cambridgeport curb adapter is proudly built right here in the USA, using high-quality American steel and the skilled craftsmanship of union tradespeople. Our team’s expertise ensures every weld, cut, and fit meets the highest standards of strength and precision. By keeping our manufacturing local, we not only deliver superior durability and performance, but also support American jobs and the communities where we live and work.